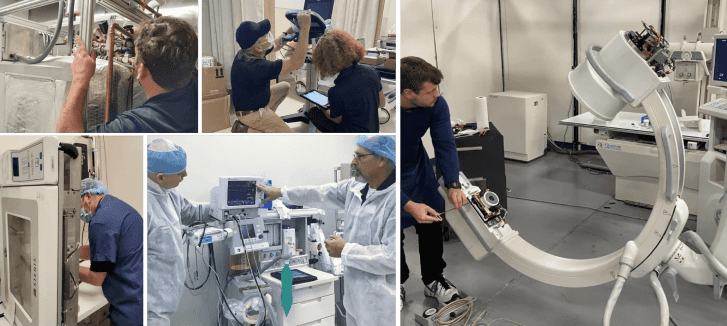

The reliability of your medical equipment is not merely a matter of convenience—it is a critical component of patient safety and operational success. At Auxo Medical, we understand that when your equipment goes down, patient care pauses, revenue is lost, and stress levels rise. That is why we have dedicated our business to providing the highest standard of service, maintenance, and repairs in the industry.

We believe that medical facilities—whether large hospital networks, ambulatory surgery centers (ASCs), or university laboratories—deserve a partner who cares as much about the uptime of their devices as they do. From routine Preventative Maintenance (PM) to emergency corrective repairs and comprehensive electrical safety inspections, we are your all-in-one solution for medical equipment lifecycle management.

Below, we explore the depth of our service offerings, the importance of regulatory compliance, and why choosing Auxo Medical means choosing reliability.

The “Why” Behind Professional Maintenance

Before diving into the “what,” it is essential to understand the “why.” Medical equipment is complex, expensive, and subject to rigorous wear and tear. Ignoring the health of these machines is a liability strategy that no modern facility can afford.

At Auxo Medical, we approach maintenance with three main goals in mind:

- Patient Safety: A miscalibrated monitor or a sterilizer failing a Bowie-Dick test can lead to misdiagnoses or operational infections. Our primary job is ensuring your tools work exactly as intended.

- Regulatory Compliance: The healthcare industry is governed by strict standards from organizations like the Joint Commission (TJC), the Accreditation Association for Ambulatory Health Care (AAAHC), the National Fire Protection Association (NFPA), and the Association for the Advancement of Medical Instrumentation (AAMI). We ensure your facility remains audit-ready at all times.

- Asset Longevity (ROI): Capital equipment is a massive investment. Through our proactive maintenance programs, we extend the usable life of your machinery, delaying the need for costly replacements and maximizing your return on investment.

Preventative Maintenance (PM): The Proactive Approach

The cornerstone of our service division is our Preventative Maintenance (PM) program. Many facilities fall into the trap of “run-to-failure” maintenance—fixing things only when they break. We advocate for a proactive approach that identifies potential failures before they cause downtime.

What Our PM Inspections Entail

When our trusted technicians arrive at your facility for a PM visit, we aren’t just checking boxes. We perform deep diagnostics based on Original Equipment Manufacturer (OEM) specifications.

Our process includes:

- Visual Inspections: Checking for physical damage, wear on cables, and structural integrity.

- Calibration: Ensuring device readings (pressure, temperature, heart rate, etc.) are accurate to within strict tolerances.

- Cleaning and Lubrication: Removing dust and debris that cause overheating and lubricating moving parts to prevent friction wear.

- Performance Testing: Running the machine through its full cycle to ensure functionality.

We offer PM services for a vast array of equipment, including but not limited to anesthesia machines, patient monitors, surgical tables, exam lights, defibrillators, and electrosurgical units (ESU).

Documentation and Compliance

In the modern medical environment, if it isn’t documented, it didn’t happen. Upon completion of our PM services, we provide detailed service reports. These digital records are crucial for your accreditation surveys. We track the history of every asset we touch, giving you a transparent view of your inventory’s health.

Corrective Maintenance: Rapid Response Repairs

Even with the best preventative care, components fail. Electronic boards short out, hydraulic seals leak, and mechanical gears strip. When the unexpected happens, our Corrective Maintenance team is ready to deploy.

We pride ourselves on our ability to troubleshoot and repair equipment efficiently. Because we are a company that also specializes in refurbishment and sales, we have extensive access to supply chains for parts that other third-party service organizations might struggle to find.

Minimizing Downtime

We know that a broken autoclave in a sterile processing department can bottle-neck an entire day’s surgery schedule. Our technicians are trained to diagnose issues quickly. We assess the fault, provide a transparent quote for the repair, and work diligently to get your equipment back online.

Whether it is a minor repair on an infusion pump or a major overhaul of a washer-disinfector, we apply the same level of technical rigor. Our goal is always “first-time fix,” reducing the need for return visits and getting your clinicians back to work faster.

Specialized Expertise: Sterilization and Washing Equipment

While we service a broad spectrum of biomedical equipment, Auxo Medical is widely recognized for our specialized expertise in Sterile Processing Department (SPD) equipment.

Sterilizers (autoclaves) and washer-disinfectors are the workhorses of the hospital. They operate under high heat, high pressure, and constant moisture—conditions that are brutal on machinery.

Our Sterilizer Services Include:

- Chamber Cleaning: Mineral buildup and scale can compromise sterilization cycles and damage instruments. We perform professional descaling and chamber cleaning.

- Valve and Trap Maintenance: We inspect and replace steam traps, safety valves, and door gaskets to prevent leaks and vacuum failures.

- Control System Upgrades: For older units that are mechanically sound but electronically obsolete, we can often upgrade controls to extend the unit’s life.

By maintaining your SPD equipment with Auxo Medical, you ensure that your surgical instruments are sterile, safe, and ready for the operating room, reducing the risk of Surgical Site Infections (SSIs).

Electrical Safety Inspections (ESI)

One of the most critical—yet often overlooked—aspects of medical equipment maintenance is electrical safety. Patients in hospitals are often particularly vulnerable to electric shock, especially if they have invasive lines or catheters.

We conduct rigorous Electrical Safety Inspections in accordance with NFPA 99 standards.

Using state-of-the-art analyzers, our technicians test for:

- Ground Wire Resistance: Ensuring the grounding path is intact to direct stray current away from the patient.

- Chassis Leakage Current: Measuring any unintended electrical current flowing through the casing of the device.

- Lead Leakage: Ensuring no dangerous current flows through patient-connected leads (like ECG leads).

These inspections are mandatory for compliance, but more importantly, they save lives. We integrate ESI into our regular maintenance schedules so you never have to worry about the electrical integrity of your fleet.

Biomedical Engineering Services

For facilities that do not have an in-house clinical engineering department, Auxo Medical acts as your dedicated biomedical team. We offer varying levels of service contracts to fit the unique needs and budget of your facility.

- Full-Service Contracts: A comprehensive “insurance policy” for your equipment. This typically covers all labor, travel, and parts for repairs and PMs. It offers a predictable budget with no surprise costs.

- PM-Only Contracts: We handle the scheduled maintenance to keep you compliant, while repairs are billed on a time-and-materials basis. This is often ideal for newer fleets with active warranties.

- Time and Materials: No contract required. You simply call us when you need us.

We also assist with Incoming Inspections. Whenever you buy new or refurbished equipment, it must be inspected and tagged before it enters clinical use. We handle this process, ensuring every device added to your inventory is safe and logged into your asset management system.

The Auxo Medical Difference: Sustainability and Refurbishment

What sets us apart from other service providers is our holistic view of the equipment lifecycle. We are not just a repair company; we are a refurbishment company.

If a piece of equipment is deemed “beyond economic repair” by other standards, we often see potential. We are committed to sustainable healthcare practices. If we can refurbish a device to meet original manufacturer specifications for a fraction of the cost of buying new, we will present that option.

This capability allows us to offer loaner equipment in many scenarios. If your critical device needs to be taken off-site for a major repair, we may be able to provide a rental or loaner from our inventory to keep your facility running smoothly.

Field Service That Covers You

Our team of field service technicians is factory-trained and strategically located to provide prompt service. We invest heavily in the continuous education of our staff because medical technology is always evolving. From the legacy hydraulic tables to the latest digital diagnostic sets, our team has the knowledge base to handle it.

We serve a wide variety of clients, including:

- Hospitals and Health Systems

- Ambulatory Surgery Centers (ASCs)

- Medical Research Laboratories

- Universities and Educational Institutions

- Private Practices and Clinics

Partner with Us for Peace of Mind

At Auxo Medical, we believe that service is not just about fixing machines; it is about serving the people who rely on them. Every time we calibrate a monitor or repair a sterilizer, we know that a patient’s well-being is ultimately on the line.

By choosing us for your service, maintenance, and repair needs, you are choosing a partner dedicated to transparency, compliance, and quality. We take the burden of equipment management off your shoulders, allowing your doctors, nurses, and technicians to focus on what they do best: healing patients.

Ready to Optimize Your Equipment Strategy?

Do not wait for an emergency to think about your maintenance strategy. Whether you need a one-time repair, an electrical safety inspection, or a comprehensive annual service contract, we are here to help.

Contact Auxo Medical today. Let us assess your inventory and build a customized service plan that ensures your facility remains safe, compliant, and efficient for years to come. Together, we can ensure that your technology never misses a beat.