Description

Steris AMSCO Century SG-148 Scientific Steam Sterilizer

Steris SG-148 Scientific Steam Sterilizers are designed for fast, efficient sterilization. The SG-148 gravity sterilizer is equipped with pre-vac, gravity, flash, express, leak test, and daily air removal test cycles. With a 26″ x 37.5″ x 48″ (767 Liters) chamber, the SG148 sterilizer provides enough space fit all of your equipment and sterilize with speed and reputable quality in mind and designed for sterilization of nonporous heat- and moisture-stable goods, sterilization of liquids and media applications. This laboratory steam sterilizer provides high quality repeatable performance and accountability for a wide range of lab applications, including: liquids, media, glassware, instruments, clothing, waste, media clothing and laboratory items.

Features:

- Florescent display for easy reading

- Ink on paper impact printer

- 26″ x 37.5″ x 48″ chamber (767 Liters)

- Gravity Steam Sterilizer

- Fast & efficient

- Emergency manual exhaust valve

- Non-lubricated, steam-activated door seal

- Help screens for programming/troubleshooting alarm conditions

- Communication interface compatibility w/ most PC devices

- Electronic water conservation valve

- Optional Stainless steel side panels available.

Additional Options:

- Cabinet Package

- Loading Cart

- Integral Steam Generator

- Water Filtration Options

Breakdown of Prevacuum vs. Gravity

- Gravity - designed for sterilization of liquids in flasks with vented closures, at 250°F (121°C), and also heat- and moisture-stabile goods at 270°F (132°C).

- Prevacuum – designed for efficient, high-volume processing of heat- and moisture-stabile materials, such as fabrics, wrapped hard goods, glassware or animal bedding, at 270°F (132°C). Prevacuum units will also run gravity-type cycles.

Gravity units operate by the gravity downward displacement air-removal principle. Prevacuum sterilizers have a chamber evacuation system for high-speed, high-volume sterilization. Both types use steam-under-pressure as the sterilizing agent.

Prevacuum configuration sterilizers are factory programmed with the following cycles:

- 270°F (132°C) Prevacuum (with either 5-minute or 20-minute dry phases) – For efficient, high volume processing of heat- and moisture-stable materials, such as fabrics and wrapped hard goods. This process incorporates a series of pressure/vacuum pulses to condition the load prior to sterilization. Sterilize temperature: 270°F (132°C) – Sterilize time: 4 minutes – Dry time: 5 minutes or 20 minutes

- Gravity, Liquid, 250°F (121°C) – For sterilizing fabrics, Sterilize temperature: 250°F (121°C) – Sterilize time: 30 minutes – Dry time: 15 minutes (Note: A gravity cycle, adjusted to 270°F for 25-minute sterilize exposure time, can be used for processing fabric packs.)

- 270°F (132°) Gravity Cycle: For sterilizing hard goods. Sterilize temperature: 270°F (132°C) – Sterilize time: 15 minutes – Dry time: 30 minutes (Note: 270°F temperature must be set by the user)

- SFPP configuration sterilizers are factory programmed with the following cycles: WRAP/SFPP, SFPP, Prevacuum, Gravity, Liquid and Test Cycles.

- Note: SFPP Cycle: For efficient, high-volume processing of porous loads. This process incorporates a series of steam flushes and pressure pulses at pressures above atmospheric levels to condition load prior to sterilization.

- Sterilize temperature: 270°F (132°C) – Sterilize time: 4 minutes – Dry time: 20 minutes

- WRAP/SFPP Cycle: For efficient, high-volume processing of heat- and moisture-stable materials, such as double wrapped instrument trays. This process incorporates a series of steam flushes and pressure pulses at pressures above atmospheric levels to condition load prior to sterilization. – Sterilize temperature: 270°F (132°C) – Sterilize time: 4 minutes – Dry time: 20 minutes

- Liquid Cycle: This cycle is used for sterilizing liquids in borosilicate containers with vented closures. » Sterilize temperature: 250°F (121°C) – Factory programmed sterilize time: 45 minutes – Dry time: not applicable

- 275°F (135°C) Prevacuum Cycle: This cycle is used for efficient, high-volume processing of heat- and moisturestable materials in double-wrapped instrument trays. This process incorporates a series of pressure/vacuum pulses to condition the load prior to sterilization. » Sterilize temperature: 275°F (135°C) » Sterilize time: 3 minutes » Dry time: 16 minutes

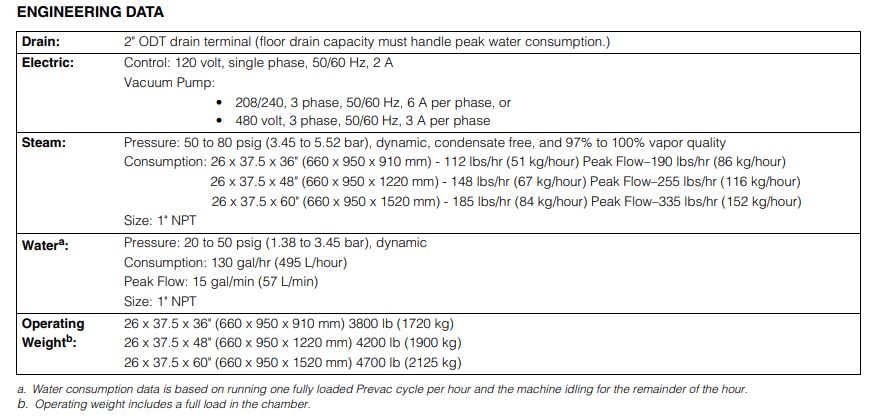

Utility Requirements:

- Steam

- 1” NPT

- 50 to 80 psig (3.5 – 5.6 bar) dynamic

- 97% – 100% vapor quality

- Drain

- 2” ODT drain terminal

- Electrical – Controls

- 120 Volt, 50/60 Hz, 1-phase, 2.0 Amp

- Electrical–Vacuum Pump

- 208/240 Volt, 50/60 Hz, 3-phase, 6 Amp per phase.

- 480 Volt, 50/60 Hz, 3-phase, 3 Amp per phase.

- Sterilizer Feed Water

- 1″ NPT, 20 to 50 psig (1.4 to 3.5 bar) dynamic. Water is used for vacuum pump, heat exchanger and trap cooling.