What is the difference between the two configurations: Gravity & Prevacuum?

Gravity – designed for sterilization of liquids in flasks with vented closures, at 250°F (121°C), and also heat- and moisture-stabile goods at 270°F (132°C).

Prevacuum – designed for efficient, high-volume processing of heat- and moisture-stabile materials, such as fabrics, wrapped hard goods, glassware or animal bedding, at 270°F (132°C). Prevacuum units will also run gravity-type cycles.

Gravity units operate by the gravity downward displacement air-removal principle. Prevacuum sterilizers have a chamber evacuation system for high-speed, high-volume sterilization. Both types use steam-under-pressure as the sterilizing agent.

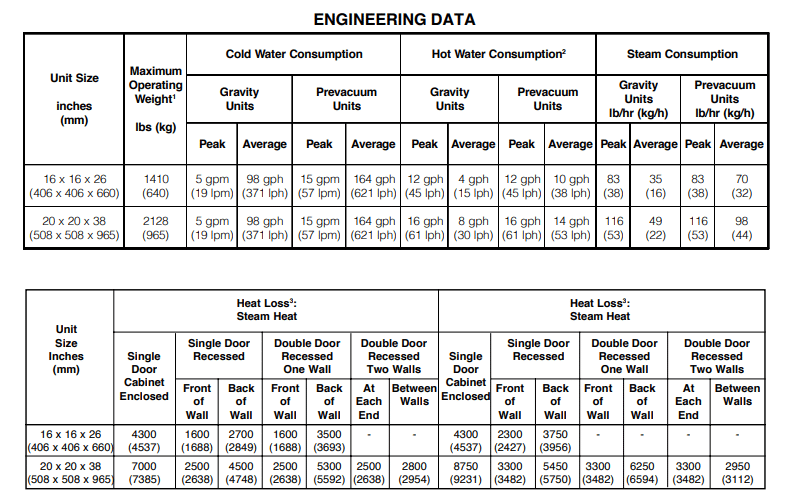

Utility Requirements

All utility supplies should have manual shutoffs located where the sterilizer connects to the utilities. Any utilities supplied above the sterilizer should be directed downward.

Cold Water (C)

• 80° F (26.7° C) maximum.

• A 1” minimum NPT fitting should be provided.

• Vacuum Sterilizer (3013 & 3023):

• 30 to 50 minimum dynamic/static psig (206.8 – 344.7 kPa)

• Peak consumption is 15 GPM; Average consumption is 164 GPH.

Cold Water (C) for Unit with Reimers Steam Generator

• ½” NPT

• 20 to 50 psig (137.9 – 344.7 kPa) dynamic

• Refer to recommended quality under cold water listing.

Steam (S) (House-Steam Units only)

A steam trap should be installed in the line immediately upstream of the utility shutoff.

A ½” NPT fitting should be available.

50-80 psig (344.7 – 551.6 kPa) dynamic/static

Drain (D)

• 1- ½” ODT drain terminal and floor drain capable of handling peak water consumption.

• The drain line must be connected to a receiver capable of withstanding 140° F water otherwise a drain cooler will be required.

Electricity (E)

• Outlet box for 120 VAC, 50/60 Hz, 1 Amp (5.5 Amps for electric units) electric service to the sterilizer controls.

Generator Electricity (G) (Electric Units only)

• Steam Generator

• Outlet box for 120 VAC, 60 HZ, 7 Amp electrical service for the steam generator control.

Terminal box for 208 or 480 Volt, 50/60 Hz, 3-phase service to the optional integral electric steam generator heaters.

All configurations require a ground.