Description

Steris AMSCO Stage 3 Series 16″ 3013 Sterilizer

Refurbished Steris Amsco Model 3013 Steam Sterilizer includes: Stage 3 Controller with thermal printer, For Recess Mount, Chamber DIMS 16 x 16 x 26, Prevacuum (Class B), Thermal display with touchpad operation.

Features:

- Stage 3 controller with thermal printer

- Single Radial arm manual door (optional hinge)

- Recess Mount

- Interior chamber size of 16″ x 16″ x 26″

- Pre-vacuum configuration

- Thermal display with touch pad operation

- Hydrostatically tested pressure chamber

Warranty: 1 Year Parts & Labor, 6 months on PM Parts, 5 years on pressure vessel.

Additional Information:

- All refurbished steam sterilizers are fully disassembled and rebuilt using all OEM parts and procedures.

- Optional Stainless steel side panels available.

- Optional 30kW steam generator for electrical units.

- Standard Preventative Maintenance must be completed while unit is under warranty

- Additional freight and installation charges apply.

What is the difference between the two configurations: Gravity & Prevacuum?

- Gravity - designed for sterilization of liquids in flasks with vented closures, at 250°F (121°C), and also heat- and moisture-stabile goods at 270°F (132°C).

- Prevacuum – designed for efficient, high-volume processing of heat- and moisture-stabile materials, such as fabrics, wrapped hard goods, glassware or animal bedding, at 270°F (132°C). Prevacuum units will also run gravity-type cycles.

Gravity units operate by the gravity downward displacement air-removal principle. Prevacuum sterilizers have a chamber evacuation system for high-speed, high-volume sterilization. Both types use steam-under-pressure as the sterilizing agent.

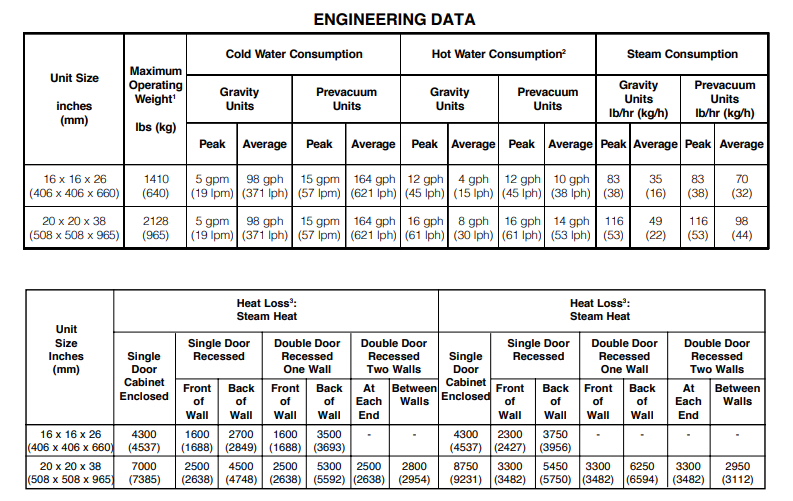

Utility Requirements:

Cold Water (C)

- 80° F (26.7° C) maximum.

- A 1” minimum NPT fitting should be provided.

- Vacuum Sterilizer (3013 & 3023):

- 30 to 50 minimum dynamic/static psig (206.8 – 344.7 kPa)

- Peak consumption is 15 GPM; Average consumption is 164 GPH.

- ½” NPT

- 20 to 50 psig (137.9 – 344.7 kPa) dynamic

- Refer to recommended quality under cold water listing.

- A steam trap should be installed in the line immediately upstream of the utility shutoff.

- A ½” NPT fitting should be available.

- 50-80 psig (344.7 – 551.6 kPa) dynamic/static

- 1- ½” ODT drain terminal and floor drain capable of handling peak water consumption.

- The drain line must be connected to a receiver capable of withstanding 140° F water otherwise a drain cooler will be required.

- Outlet box for 120 VAC, 50/60 Hz, 1 Amp (5.5 Amps for electric units) electric service to the sterilizer controls.

- Steam Generator

- Outlet box for 120 VAC, 60 HZ, 7 Amp electrical service for the steam generator control.

- Terminal box for 208 or 480 Volt, 50/60 Hz, 3-phase service to the optional integral electric steam generator heaters.