Description

Refurbished Steris Amsco Model 3013 Steam Sterilizer includes: Stage 3 Controller with thermal printer, For Recess Mount, Chamber DIMS 16 x 16 x 26, Prevacuum (Class B), Thermal display with touchpad operation.

Fully Refurbished Steris-Amsco™ model 3013 steam sterilizer features:

• Stage 3 controller with thermal printer

• Single Radial arm manual door (optional hinge)

• Recess Mount

• Interior chamber size of 16″ x 16″ x 26″

• Pre-vacuum configuration

• Thermal display with touch pad operation

• Hydrostatically tested pressure chamber

Warranty: 1 Year Parts & Labor, 6 months on PM Parts, 5 years on pressure vessel.

All reconditioned steam sterilizers are fully disassembled and rebuilt using all OEM parts and procedures.

Optional Stainless steel side panels available.

Optional 30kW steam generator for electrical units.

Standard Preventative Maintenance must be completed while unit is under warranty

Additional freight and installation charges apply.

What is the difference between the two configurations: Gravity & Prevacuum?

Gravity – designed for sterilization of liquids in flasks with vented closures, at 250°F (121°C), and also heat- and moisture-stabile goods at 270°F (132°C).

Prevacuum – designed for efficient, high-volume processing of heat- and moisture-stabile materials, such as fabrics, wrapped hard goods, glassware or animal bedding, at 270°F (132°C). Prevacuum units will also run gravity-type cycles.

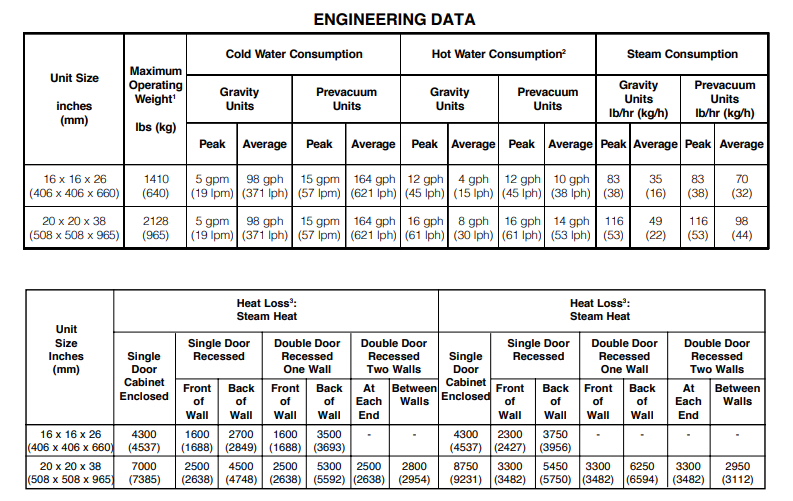

Utility Requirements

Cold Water (C)

• Peak consumption is 15 GPM; Average consumption is 164 GPH.

Steam (S) (House-Steam Units only)

50-80 psig (344.7 – 551.6 kPa) dynamic/static

• The drain line must be connected to a receiver capable of withstanding 140° F water otherwise a drain cooler will be required.