Why the Midmark M9 Autoclave is Essential for Your Dental Office

The Importance of Sterilization in Dental Offices

Sterilization is a fundamental aspect of maintaining a safe and hygienic environment in dental offices. With the potential for exposure to various infectious diseases, it becomes imperative to implement rigorous sterilization protocols to protect both patients and dental healthcare professionals.

Dental procedures often involve direct contact with bodily fluids, saliva, and contaminated instruments. Without proper sterilization practices, harmful microorganisms can easily spread, leading to cross-contamination and the transmission of infections. The consequences of inadequate sterilization can be severe, ranging from minor oral infections to more serious conditions that may even require hospitalization.

Why You Need the Midmark M9 Autoclave

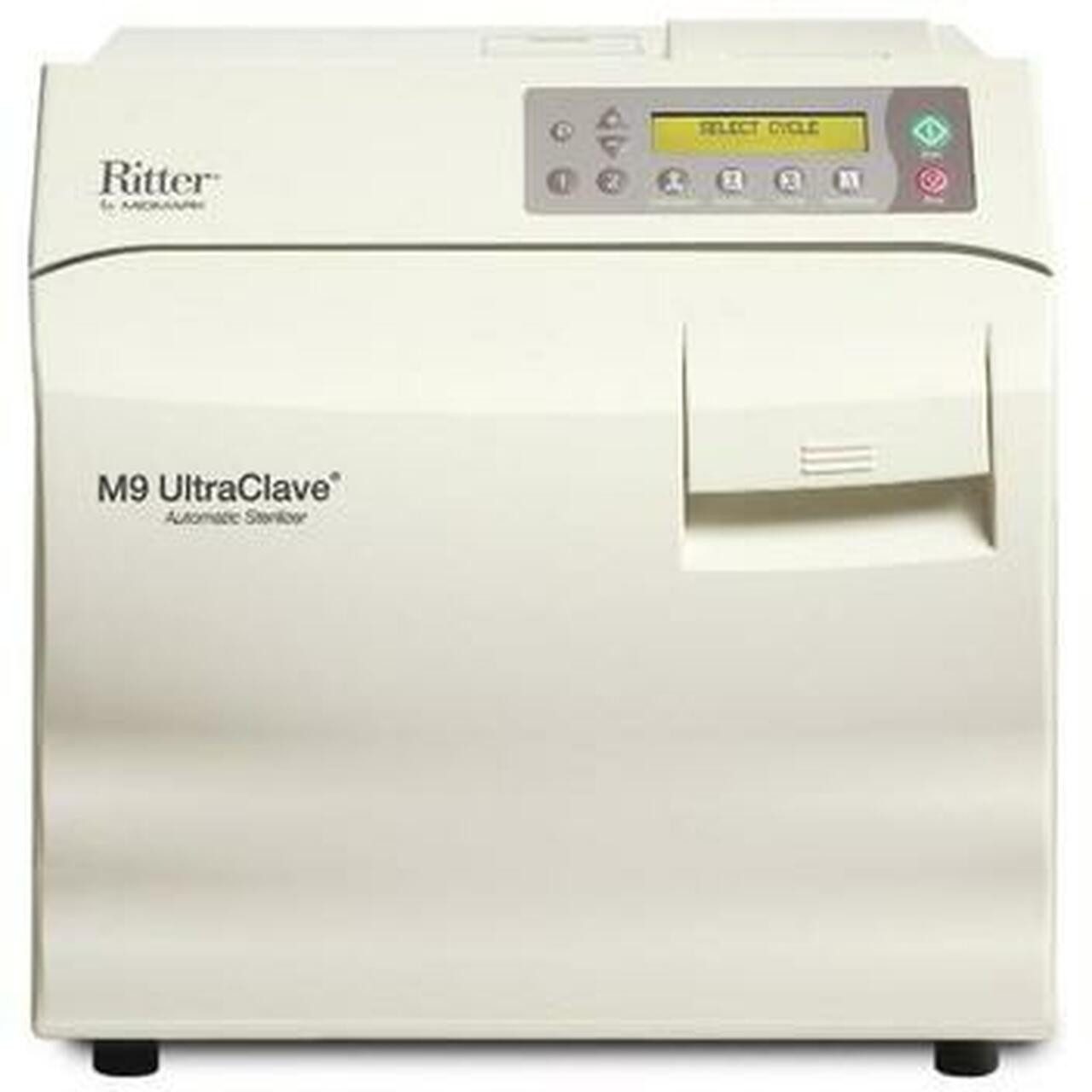

Ensuring the utmost sterilization in your dental office is of paramount importance. With the Midmark Ritter M9 UltraClave Automatic Sterilizer, you can rest assured that your instruments and equipment are thoroughly disinfected, protecting the health and safety of both your patients and staff. This advanced steam sterilizer utilizes a combination of heat, pressure, and steam to eliminate harmful microorganisms with unmatched efficiency.

This Midmark M9 autoclave is an indispensable tool for any dental practice due to its exceptional features. Its spacious chamber allows for the sterilization of various instruments simultaneously, saving precious time during busy clinic hours. The intuitive one-touch control system ensures easy operation, while its reliable performance guarantees consistent sterilization results. Equipped with a powerful heating element and intelligent drying cycle, the Midmark M9 autoclave leaves your instruments perfectly dry and ready for use.

The Midmark M9 Autoclave: A Highly Efficient Steam Sterilizer

The Midmark Ritter M9 UltraClave autoclave stands as a testament to the pinnacle of sterilization technology, offering dental offices an unparalleled level of efficiency and reliability. As a steam sterilizer, it harnesses the power of high-pressure steam to effectively eliminate harmful pathogens and ensure optimal disinfection of dental instruments.

With its sophisticated design and cutting-edge features, the Midmark M9 autoclave goes above and beyond industry standards. Its spacious chamber accommodates a substantial load of instruments, maximizing productivity without compromising sterilization efficacy. Equipped with intuitive controls and programmable settings, this autoclave simplifies the sterilization process, allowing dental professionals to focus on providing exceptional patient care.

Exploring the Features of the Midmark Ritter M9 UltraClave

In this section, we will delve into the remarkable features that make the Midmark Ritter M9 UltraClave an essential tool for every dental office. Designed with precision and innovation, this autoclave guarantees optimal sterilization results.

The Midmark Ritter M9 UltraClave boasts a spacious chamber that can accommodate a wide variety of instruments, ensuring efficient sterilization in every cycle. Its user-friendly control panel allows for easy operation, providing dental professionals with convenience and peace of mind. Furthermore, the intuitive LCD display provides real-time information on cycle progress and alerts, allowing for seamless monitoring.

Ensuring Proper Autoclave Maintenance for Longevity

In order to maintain the optimal performance and longevity of your Midmark M9 autoclave, and truly any autoclave, it is essential to implement a thorough maintenance routine. By following these simple yet crucial steps, you can ensure that your autoclave continues to function flawlessly, providing you with years of reliable and efficient sterilization.

First and foremost, regular cleaning is paramount. After each use, carefully wipe down the interior and exterior surfaces of the autoclave using a gentle disinfectant solution. Pay close attention to areas prone to buildup such as the chamber, trays, and door gasket. This not only prevents cross-contamination but also preserves the pristine appearance of your autoclave.

Secondly, it is imperative to regularly inspect and replace worn or damaged parts. Many autoclaves come equipped with indicator lights, error codes or alarms that alert you when certain components need attention. Take heed of these indicators and promptly address any issues by contacting a professional service provider like Auxo Medical who specializes in autoclave repair and maintenance.

Lastly, proper water quality is crucial for optimal autoclave function. Utilize distilled or deionized water in every cycle to minimize mineral buildup within the machine which can lead to reduced efficiency over time. Investing in a water treatment system may prove fruitful in maintaining your autoclave’s performance.

By adhering to these maintenance practices diligently, you can ensure that your autoclave remains a reliable workhorse in your dental office for years on end. The peace of mind that comes with knowing your sterilization equipment is functioning at its best will undoubtedly

How Auxo Medical Can Help You with Autoclave and Sterilizer Needs

When it comes to ensuring the smooth operation of your dental office, having a reliable partner to assist you with your autoclave and sterilizer needs is crucial. That’s where Auxo Medical comes in. With our extensive expertise in the field, we are dedicated to providing top-notch solutions tailored specifically for dental professionals.

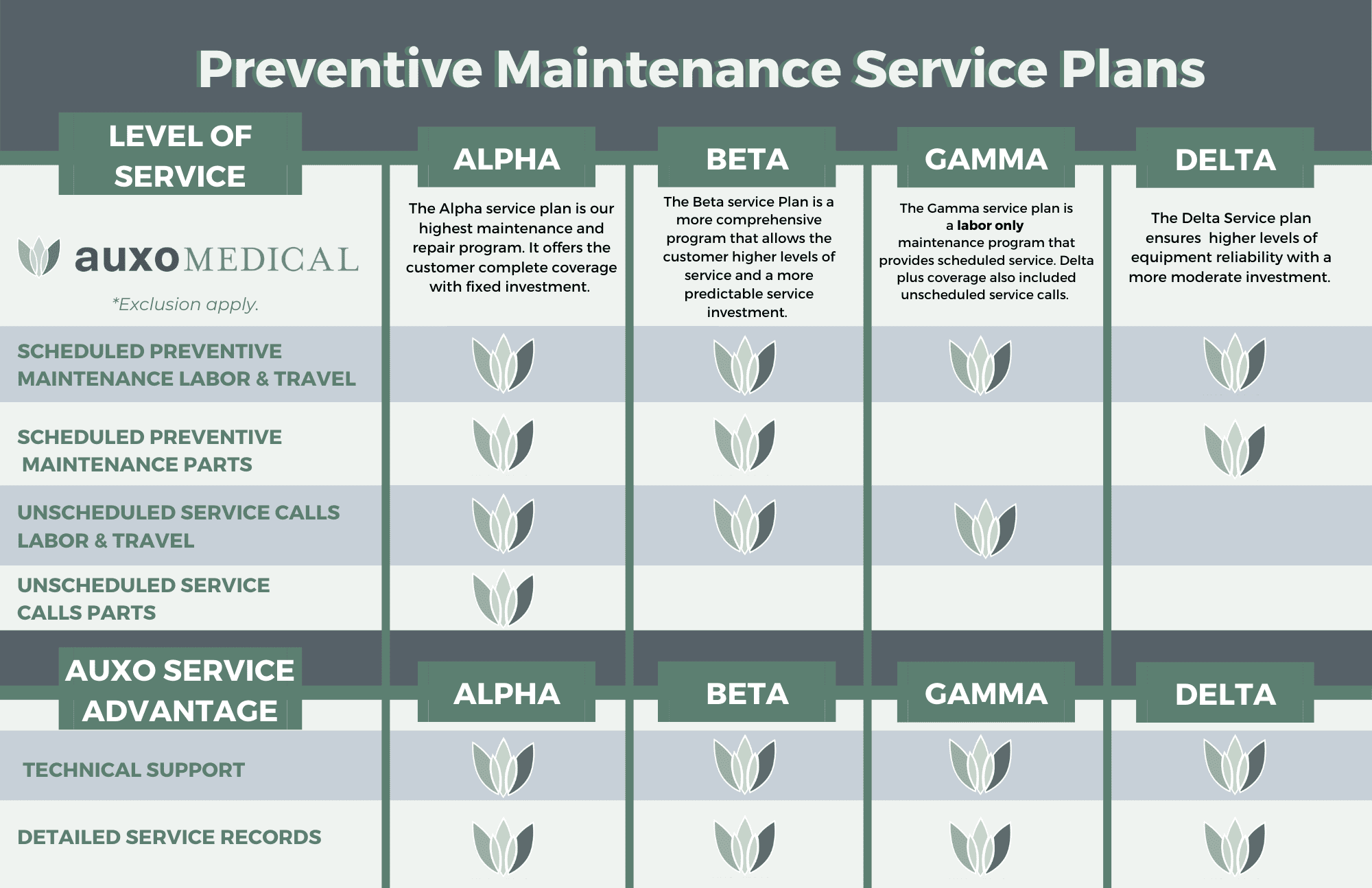

Auxo Medical understands that every dental office has unique requirements when it comes to sterilization equipment. We offer a wide range of services, including autoclave sales, repairs, and preventive maintenance plans, all designed to meet your specific needs. Whether you’re looking to purchase the Midmark Ritter M9 UltraClave or need assistance with maintaining your existing equipment, Auxo Medical has got you covered.

With our team of highly trained technicians, Auxo Medical ensures that your autoclave operates at its peak performance. We provide thorough inspections and expert repairs whenever necessary to keep your sterilization processes running smoothly. Additionally, our preventive maintenance plans help extend the lifespan of your equipment and minimize any potential disruptions in your practice.

What sets Auxo Medical apart is not only our technical expertise but also our commitment to customer satisfaction. We prioritize building lasting relationships with our clients by delivering exceptional service and support throughout the entire process. With Auxo Medical by your side, you can rest assured knowing that your autoclave and sterilizer needs are in capable hands.

Purchase your Midmark M9 Autoclave From Auxo Medical

When it comes to investing in a top-of-the-line autoclave for your dental office, there’s no better place to turn than Auxo Medical. With decades of experience in the industry and a reputation for excellence, our team is dedicated to providing you with the highest quality equipment and exceptional customer service.

By choosing Auxo Medical as your supplier, you can rest assured that you are getting a genuine Midmark Ritter M9 UltraClave Automatic Sterilizer that will meet all of your sterilization needs. Not only does this renowned autoclave offer advanced features and cutting-edge technology, but with Auxo Medical, you also benefit from our expertise in installation, maintenance, and repair services. Request a Quote below or call our office toll-free at (888) 728-8448.

Midmark Ritter M9 UltraClave (Autoclave), M9-022

Request Quote

The Midmark Ritter M9 UltraClave is a user-friendly automatic sterilizer designed for simple and reliable operation. Its automated features streamline the sterilization process: simply load the instruments, select the desired cycle, and press start. The M9 automatically fills with the correct water level and, upon cycle completion, automatically opens the door for efficient steam dissipation and faster drying times. Built-in safety features, including overheat protection, a pressure relief valve, and an error light, ensure safe and reliable performance. Self-program controls allow customization of cycle parameters to accommodate specific instrument processing needs, while pre-programmed cycles offer convenience for routine sterilization. The green LCD display provides clear visibility of cycle indicators. The M9 is commonly used in various healthcare settings such as dental clinics, medical offices, veterinary practices, and other outpatient facilities where efficient and reliable sterilization of instruments is critical. Its ease of use and compact design make it well-suited for smaller practices and labs. Industries beyond healthcare, such as tattoo parlors and beauty salons, may also utilize the M9 for sterilizing tools and equipment.

Description

Midmark Ritter M9 UltraClave (Autoclave), M9-022

The Midmark Ritter M9 Ultraclave automatic sterilizer is an autoclave that couldn’t be easier and is time tested for reliability. You load it set it and forget it. Select your cycle and the time is set for you. Press Start and the Midmark M9 fills with the correct amount of water. Once the sterilization process is complete, the door opens automatically and quietly to dissipate the steam to give you fast drying time for your instruments. Its real convenience!

Features:

- Fills with correct amount of water when you hit the start button.

- Door opens automatically to dissipate steam and give you the fastest drying time.

- Built-in safety features such as overheat protection, a pressure relief valve and flashing “Error” light.

- Self Program Controls enable you to create different cycle parameters to meet specific instrument processing needs

- Green LCD Display for easy view of indicators

For Use in Industries:

- Medical offices

- Dental clinics

- Veterinary practices

- Outpatient facilities

- Research and medical laboratories

- Tattoo parlors

- Beauty salons

- Estheticians

For Sterilization of:

- Handpieces: Dental and surgical handpieces.

- Instruments: Scalpels, forceps, scissors, curettes, probes, and other surgical instruments.

- Needles: Hypodermic needles (in appropriate containers).

- Surgical burs: Used in dental procedures.

- Endodontic files: Used in root canal procedures.

- Glassware: Beakers, test tubes, and other laboratory glassware (heat-resistant).

- Metal instruments: Retractors, clamps, speculums.

- Plastic instruments: Certain heat-resistant plastics and polymers used in medical devices.

- Rubber items: Certain heat-resistant rubber items.

- Fabric: Wrapped instrument packs and certain heat-resistant fabrics.

- Tattoo needles: Properly packaged and in appropriate containers.

- Grips and tubes: Metal grips and tubes used with tattoo machines.

- Stainless steel jewelry: Body jewelry made of surgical stainless steel.

- Metal tools: Scissors, forceps, and other metal tools used during the tattooing process.

- Metal implements: Comedone extractors, tweezers, nail clippers, cuticle pushers, and other metal tools used in facials, manicures, and pedicures.

- Scissors and razors: Hair cutting scissors and razors (if compatible with steam sterilization).

- Glassware: Small glass containers used for mixing products (if heat-resistant)

Important Considerations:

- Manufacturer’s Instructions: Always consult the instrument or device manufacturer’s instructions for compatibility with steam sterilization.

- Packaging: Items should be properly packaged to ensure steam penetration and maintain sterility after the cycle.

- Materials Compatibility: Not all materials can withstand steam sterilization. Avoid sterilizing heat-sensitive materials, liquids in sealed containers, and items that can be damaged by moisture.

- Cleaning: Thoroughly clean instruments before sterilization to remove debris and bioburden. (Cleaning of instruments in a small facility can be assisted with undercounter or countertop washer disinfectors or ultrasonic cleaners)

Additional information

| Condition |

|---|

A washer-disinfector is an essential piece of equipment in medical, laboratory, and clinic settings. It is a machine that combines the processes of washing and disinfecting to ensure optimal cleanliness of medical equipment, surgical instruments, glassware, and other tools used in these settings.

A washer-disinfector is an essential piece of equipment in medical, laboratory, and clinic settings. It is a machine that combines the processes of washing and disinfecting to ensure optimal cleanliness of medical equipment, surgical instruments, glassware, and other tools used in these settings. As an essential piece of equipment for medical, laboratory, and clinic settings, investing in a

As an essential piece of equipment for medical, laboratory, and clinic settings, investing in a