Medical Decontamination Equipment Sold by Auxo Medical

Sterilizers

Washer-Disinfectors

If you’re looking to effectively decontaminate and sterilize your medical equipment, investing in a washer-disinfector from Auxo Medical is the way to go. You can rest easy knowing that you have selected from a range of medically compliant products that will ensure your facility’s instrument washing and disinfecting needs are met accurately.

With the option of a service agreement, you can ensure that your washer-disinfector remains functional and efficient throughout its lifespan, guaranteeing optimal service and peace of mind for your patients.

Ultrasonic Cleaners

If you’re looking for a medical cleaning solution that is both gentle and effective, ultrasonic cleaners from Auxo Medical are the way to go. With your purchase, you receive a 5% discount if you opt for a service agreement, ensuring your equipment remains functional and well-maintained throughout its lifespan.

Autoclaves

Autoclaves are a type of pressure chamber that is commonly used for sterilizing equipment and materials. They use high-pressure steam to kill bacteria, viruses, and other microorganisms that may be present on surfaces or inside instruments. Autoclaves are widely used in medical settings, such as hospitals and clinics, as well as in laboratories and industrial settings where sterile conditions are required. They come in a variety of sizes and types, ranging from small tabletop models to large industrial units that can process large volumes of materials at once. Proper use and maintenance of autoclaves are essential for ensuring the safety and efficacy of the sterilization process.

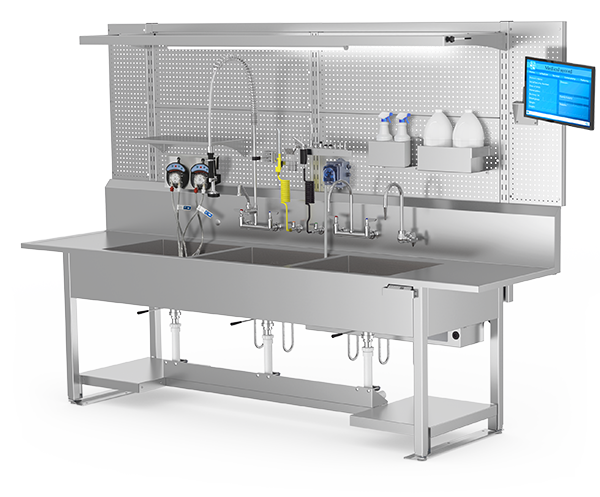

Processing Sinks

By investing in a processing sink from Auxo Medical, you can guarantee that your medical equipment is always cleaned accurately and efficiently. A bonus when you purchase the processing sink is that you can receive a 5% discount with a service agreement, ensuring continued functionality and quality.

Purchase Your Decontamination Equipment from Auxo Medical

Investing in the right medical decontamination equipment is essential to maintaining high-quality standards and promoting patient safety. The range of sterilizers, washer-disinfectors, ultrasonic cleaners, and processing sinks from Auxo Medical provides medical facilities with reliable, efficient, easy-to-use cleaning solutions. When purchasing medical decontamination equipment from Auxo Medical, you can be assured that you are getting high-quality products that are compliant with medical standards. With your purchase, you can opt for a service agreement, guaranteeing that you never have to worry about the functionality or efficacy of your medical equipment.

For those who sign up for a service agreement, you will receive a 5% discount on all medical equipment purchases from Auxo Medical. This is to ensure that from purchase to usage of the medical equipment, your operation is efficient, effective, and well maintained. Contact us today for your all-in-one decontamination equipment and service needs.

Processing Sinks What You Need to Know

Beneath the Surface: The Intriguing World of Processing Sinks

What are Processing Sinks?

Processing sinks are essential equipment for any laboratory that deals with chemicals, biological samples, or both. They are specially designed sinks that are built to withstand prolonged contact with harsh chemicals and are often used for cleaning and sterilizing laboratory equipment. Processing sinks come in a range of sizes to accommodate various laboratory settings, and they can be made from different materials such as stainless steel, Teflon, and epoxy resin.

The Importance of Processing Sinks

Processing sinks are critical to maintaining the cleanliness and safety of a laboratory environment. They provide a designated area for washing and sterilizing laboratory equipment, preventing cross-contamination between different samples and experiments. Proper maintenance of processing sinks is also essential to prevent the accumulation of bacteria, mold, and other contaminants, which can lead to unwanted results and even compromise the health of laboratory personnel.

Unlocking the Mysteries of Processing Sinks: Your Ultimate Guide

Tips for Maintaining Processing Sinks

To ensure the longevity of processing sinks and prevent the buildup of contaminants, it is crucial to perform routine maintenance. This can include regularly cleaning the sink with a non-abrasive cleaner, wiping down the sink after each use, and disinfecting the sink with a sterilizing agent. Avoid using harsh chemicals or abrasive materials when cleaning the sink, as this can damage the sink’s surface and compromise its effectiveness.

Choosing the Right Processing Sink

When choosing a processing sink, consider the type of research or testing that will be conducted in the laboratory. Stainless steel sinks are the most common choice for processing sinks, as they are durable, non-reactive, and easy to clean. However, if the laboratory uses harsh chemicals that may react with stainless steel, alternative materials such as Teflon, epoxy resin, or polypropylene may be a better choice.

Installation and Placement of Processing Sinks

Proper installation and placement of processing sinks are critical to their effectiveness and safety. Sinks should be installed by a professional, ensuring that they are properly mounted and fitted with the appropriate plumbing. Sinks should also be placed in areas that are easily accessible and free from obstruction, allowing for easy cleaning and use.

Looking for the right Processing / Decontamination Sink for your facility?

Auxo Medical has a wide variety of processing and decontamination sinks to choose from. View our available processing sink catalogue online or contact our sales team for a detailed and customized quote for your facility.