Life Sciences Sterilizers Available Through Auxo Medical

When it comes to maintaining the highest standards of sterilization in life sciences facilities, having reliable, high-performance equipment is non-negotiable. Auxo Medical partners with the most trusted and innovative manufacturers in the medical sterilization industry to ensure that our customers have access to the highest-quality equipment available. Our comprehensive selection of life sciences sterilizers features both new and refurbished options from industry-leading brands, providing cost-effective solutions without compromising on quality or performance.

Why Choose Life Sciences Sterilizers from Auxo Medical?

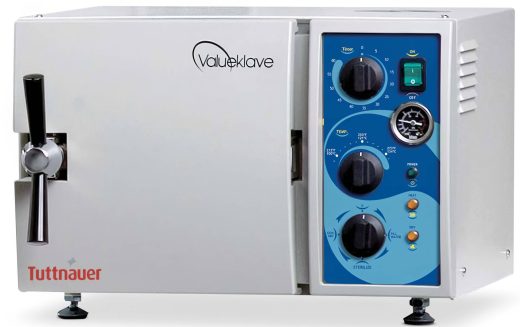

Auxo Medical proudly carries industry standard medical sterilizers from some of the world’s most respected brands, like Steris, Tuttnauer, and more. In addition, Auxo Medical’s selection of refurbished and new sterilizers provide the latest standard for steam and dry heat sterilization.

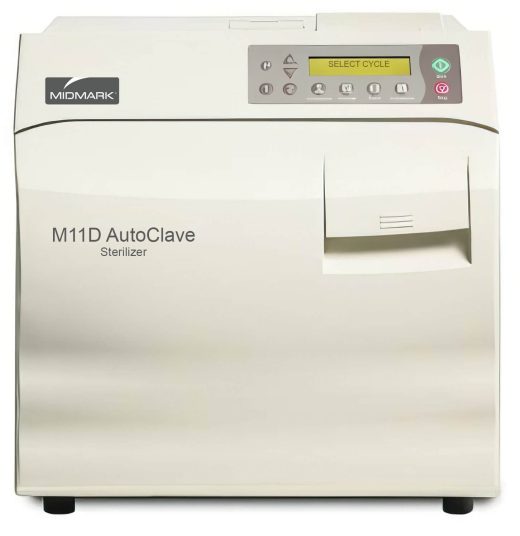

Our medical sterilizers offer numerous features and functionality, including hands-free controls, easy-to-read displays, and thermal printing capabilities. Ultimately, these durable, easy-to-operate, corrosion-resistant sterilizers will ensure your medical facility operates at peak performance.

Featured Life Sciences Sterilizers

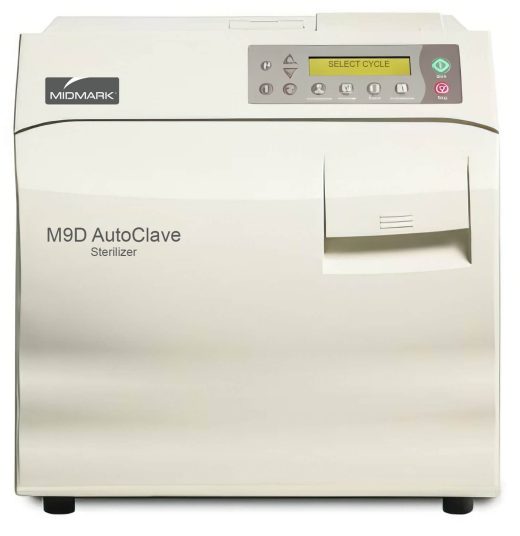

Steris 250LS 20″ Lab Sterilizer

The Steris 250LS 20” Lab Sterilizer is a state-of-the-art steam sterilizer that has been meticulously refurbished to ensure optimal performance. Designed with a spacious interior chamber measuring 20x20x38 inches, it accommodates a wide range of sterilization needs.

Key Features:

- Allen-Bradley MicroLogix™ Control System with intuitive Allen-Bradley PanelView Plus™ 7 700 interface screen

- 18-bit color graphic display with a resolution of 640 x 480 ensures clear visibility and interaction. An ink-on-paper impact printer is included for reliable documentation.

- 20 programmable cycles, including Gravity, Liquid, Prevacuum, USP 660, Continuous, and Waste Bag cycles, all stored securely in flash memory

- Rack and two-shelf loading system for enhanced versatility

- Single vertical power door with foot pedal actuation

This sterilizer is an excellent choice for laboratories seeking dependable and advanced sterilization solutions.

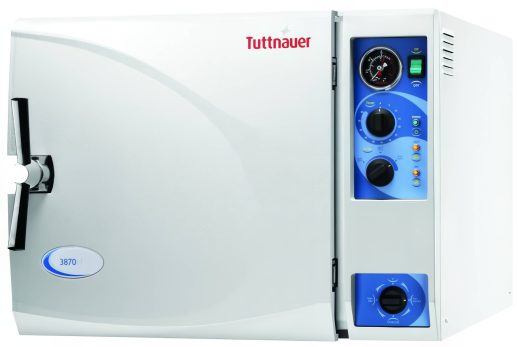

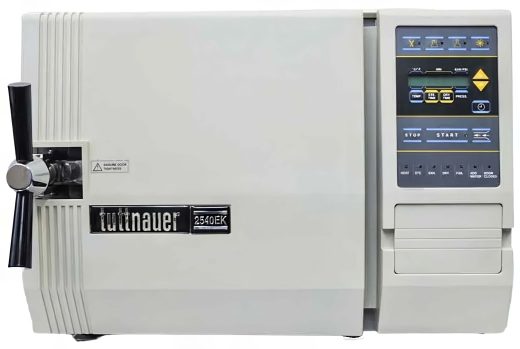

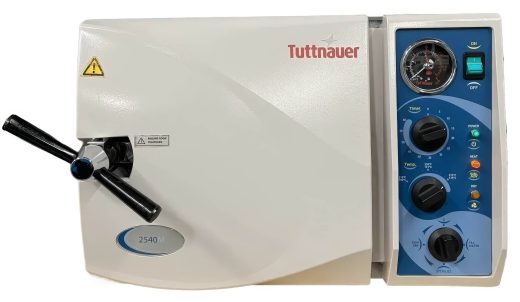

Tuttnauer Model 69B-SCP Pre-Vac Steam Sterilizer

The Tuttnauer Model 69B-SCP Pre-Vac Steam Sterilizer boasts an impressive array of features designed to meet the rigorous sterilization needs of modern laboratories and medical facilities. With its spacious internal chamber dimensions of 24″W x 36″H x 48″D, this free-standing unit is encased in a durable stainless steel cabinet and comes equipped with a single, automatic hinged door for ease of use.

Advanced Specifications:

- Utilizes house-supplied steam within a 50-80 PSI range and is controlled by a BacSoft microprocessor featuring a 7″ color touch screen for intuitive operation

- Offers a variety of cycles, including Gravity, Liquid, and Pre-Vac, along with essential test cycles like Vacuum Leak and Bowie Dick Tests

- Construction includes stainless steel threaded piping, with components made from brass and stainless steel

- Air-operated valves, liquid ring vacuum pump, and effluent condensate cooler

- Loading cart and transfer carriage included

- 1-year parts and labor warranty, alongside an extended 15-year warranty on the pressure vessel

Tuttnauer Model 5596-ECP-V Scientific Pre-Vac Steam Sterilizer

This model features internal chamber dimensions of 20W x 20H x 38D1, making it an ideal solution for laboratories with moderate sterilization needs. The scientific pre-vac design ensures thorough air removal and optimal steam penetration for consistent sterilization results.

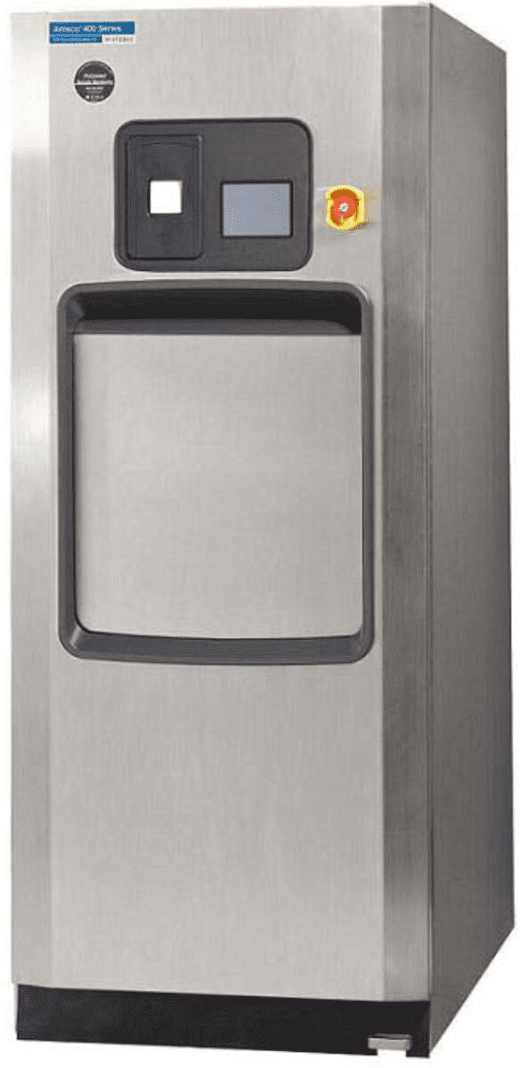

Steris Amsco 400 Series Sterilizers

Available in various sizes (48″ and 60″ chamber depths), these recessed house steam sterilizers are engineered for efficient, high-volume sterilization. We also offer cabinet packages and cart/carriage systems for the 400 series. Chamber dimensions include 26 x 37.5 inches.

The 400 Series is particularly well-suited for life sciences facilities that require high-throughput sterilization capabilities with minimal footprint.

Key Technologies and Sterilization Methods

Steam Sterilization

Steris sterilizers are designed to meet the demanding needs of hospitals, surgical centers, and other healthcare facilities, offering a comprehensive range of solutions for steam, low-temperature, and high-level disinfection.

Hydrogen Peroxide Vapor and Plasma Sterilization

For heat-sensitive materials commonly used in life sciences research, the PlazMax sterilizer inactivates micro-organisms with Hydrogen Peroxide (H2O2) vapor and plasma. It sterilizes medical devices by diffusing H2O2 into the chamber and then converting the H2O2 molecules into a plasma state.

Industries and Applications

Life sciences sterilizers from Auxo Medical serve a diverse range of industries and applications:

Research Laboratories

Life sciences research facilities, including those in universities and private research institutes, require reliable sterilization for glassware, laboratory instruments, media preparation, and biohazardous waste decontamination. Our sterilizers offer programmable cycles specifically designed for these applications.

Pharmaceutical and Biotechnology

The autoclaves cover a wide range of applications for laboratories in research institutes, universities, pharmaceutical and biotechnological industries. These facilities require validated sterilization processes for manufacturing equipment, quality control testing materials, and product development instruments.

Clinical and Diagnostic Laboratories

Medical and diagnostic laboratories need sterilizers for processing laboratory instruments, culture media, contaminated waste, and reusable medical devices. The advanced cycle monitoring and documentation features ensure compliance with regulatory standards.

Academic and Educational Institutions

Universities and teaching hospitals utilize life sciences sterilizers for student laboratory equipment, research projects, and training purposes. The user-friendly interfaces and safety features make them ideal for educational environments.

Biopharmaceutical Manufacturing

Companies involved in vaccine development, cell culture, and biologics production require sterilizers that can handle sensitive materials while maintaining strict contamination control protocols.

Common Use Cases

Glassware Sterilization: Laboratory glassware including beakers, flasks, petri dishes, and pipettes require thorough sterilization between uses. Gravity and pre-vacuum cycles ensure complete steam penetration.

Liquid Media Sterilization: Culture media, solutions, and liquids need specialized liquid cycles with controlled cooling to prevent boil-over and maintain solution integrity.

Instrument Sterilization: Surgical instruments, laboratory tools, and reusable medical devices require validated sterilization cycles with proper documentation.

Biohazard Waste Processing: Contaminated laboratory waste must be sterilized before disposal to ensure biosafety compliance.

Porous Materials: Wrapped instruments, textiles, and porous loads benefit from pre-vacuum cycles that ensure effective air removal and steam penetration.

Refurbished Equipment Advantage

Auxo Medical’s refurbished Steris sterilizers provide a cost-effective way to maintain the highest standards of sterilization without exceeding your budget. At Auxo Medical, quality and performance are our top priorities. Our reconditioned and refurbished Steris sterilizers undergo a rigorous process to ensure they meet original manufacturer specifications.

The refurbishment process includes:

- Thorough Inspection: Each sterilizer is carefully inspected to identify any potential issues.

- Cleaning and Disinfection: Sterilizers are meticulously cleaned and disinfected to ensure patient safety.

- Repair and Replacement: Any damaged or worn components are repaired or replaced with high-quality parts.

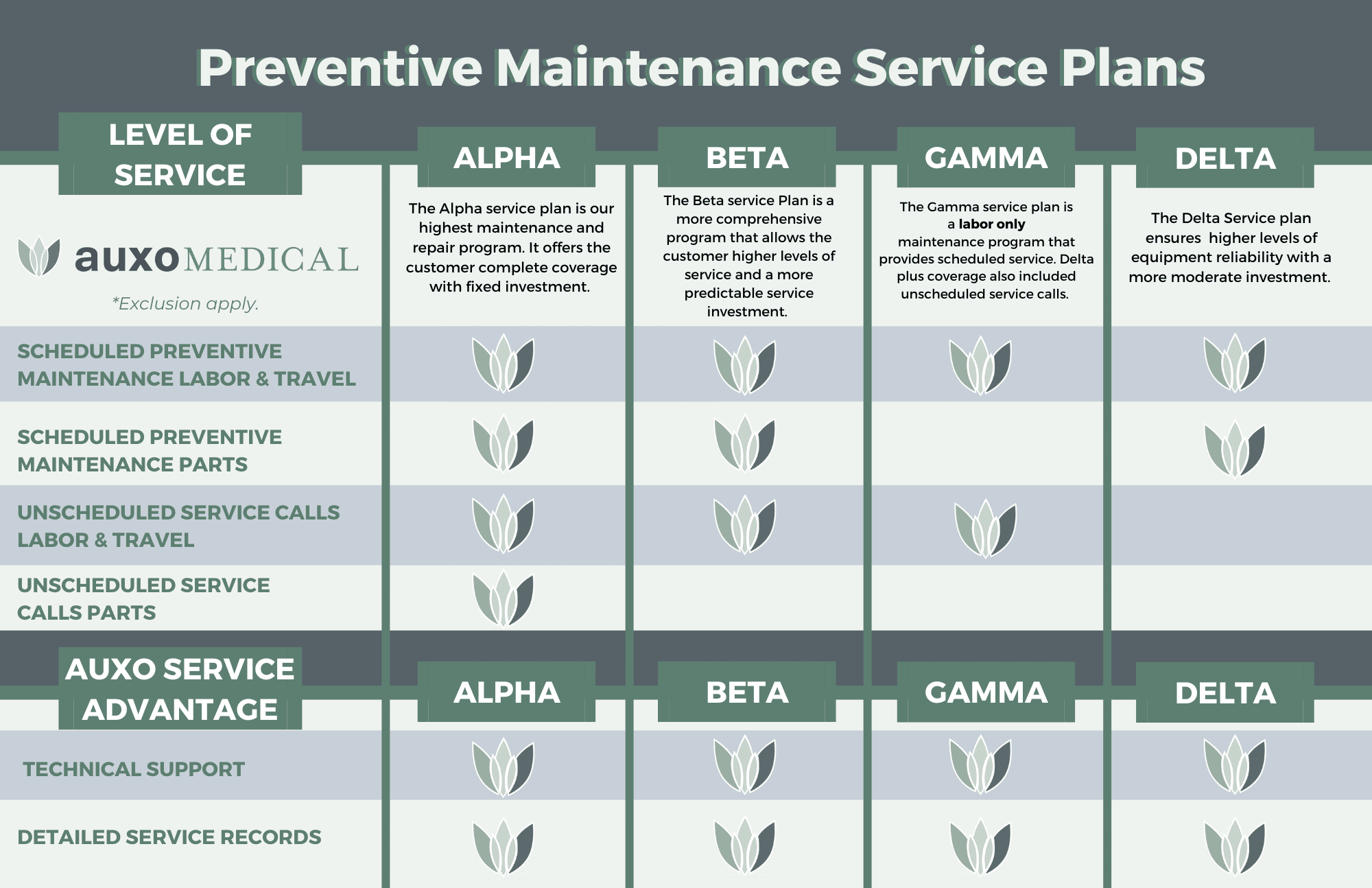

Comprehensive Support and Service

At Auxo Medical, we don’t just provide equipment – we offer comprehensive support to ensure that your lab operates at peak efficiency.

We also offer service, maintenance, and repairs for sterilizers and other medical equipment in several field service areas.

Our support services include:

- Equipment installation and validation

- Preventative maintenance programs

- Emergency repair services

- Technical training and support

- Compliance documentation assistance

Why Sterilization Matters in Life Sciences

Healthcare-associated infections (HAIs) can lead to severe complications, increased healthcare costs, and potentially life-threatening outcomes. Proper sterilization protocols are a cornerstone of infection control and patient safety in any healthcare facility.

In life sciences research, contamination can compromise years of work, invalidate experimental results, and waste valuable resources. Investing in quality sterilization equipment protects your research, ensures reproducibility, and maintains the integrity of your scientific work.

Making the Right Choice

The choice of sterilizer depends on several factors, including the type of items being sterilized, the volume of items to be processed, the available space, and the specific requirements of the facility. Auxo Medical offers a wide array of sterilizer types, sizes, and configurations to accommodate the diverse needs of the modern healthcare landscape.

When selecting a life sciences sterilizer, consider:

- Chamber size and capacity – Match your daily throughput requirements

- Cycle types needed – Ensure compatibility with materials you’ll sterilize

- Installation requirements – Consider utilities, space, and ventilation needs

- Documentation capabilities – Meet regulatory and quality assurance standards

- Budget constraints – Explore both new and refurbished options

Get Started Today

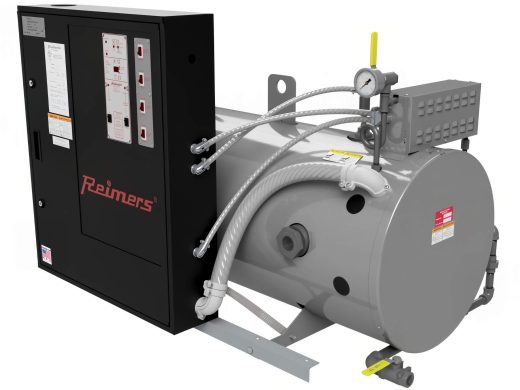

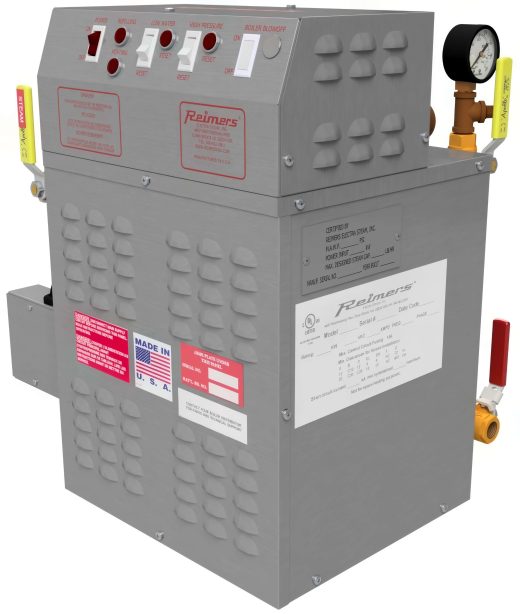

Our comprehensive range of sterilizers, boilers, glassware washers, autoclaves, centrifuges, refrigerators, and ultra-low freezers, combined with our expert services, ensures that your laboratory operates at peak efficiency.

Thank you for considering Auxo Medical as your laboratory equipment partner. We look forward to the opportunity to serve you and be a part of your laboratory’s success story.

Whether you’re setting up a new laboratory, expanding existing capabilities, or replacing aging equipment, Auxo Medical has the expertise and inventory to meet your life sciences sterilization needs. Contact us today to discuss your specific requirements and receive a customized quote for the perfect sterilizer solution for your facility.

-

Steris AMSCO Century SG-160 Scientific Steam Sterilizer

The Steris AMSCO Century SG-160 Scientific Steam Sterilizer is a large-capacity, gravity-based sterilizer designed for rapid, reliable sterilization of heat- and moisture-stable materials. Featuring a spacious 26" x 37.5" x 60" (960 liters) chamber, it provides ample room to sterilize… -

Steris AMSCO Century SV-160 Scientific Steam Sterilizer

The Steris AMSCO Century SV-160 Scientific Steam Sterilizer is a high-capacity, pre-vacuum sterilizer engineered for rapid, dependable sterilization of heat- and moisture-stable materials. Featuring a generous chamber size of 26" x 37.5" x 60" (960 Liters), it accommodates large loads… -

Steris AMSCO Century SG-148 Scientific Steam Sterilizer

The Steris AMSCO Century SG-148 Scientific Steam Sterilizer is a high-capacity, gravity-based sterilizer designed for swift, reliable processing of heat- and moisture-stable materials. Featuring a spacious 26" x 37.5" x 48" (767 liters) chamber, it provides ample room to sterilize… -

Steris AMSCO Century SV-148 Scientific Steam Sterilizer

The Steris AMSCO Century SV-148 Scientific Steam Sterilizer is a high-capacity, pre-vacuum sterilizer engineered for rapid and reliable sterilization of heat- and moisture-stable materials. Boasting a spacious 26" x 37.5" x 48" (767 liters) chamber, it accommodates large loads of… -

Steris AMSCO SG-136 Scientific Medium Steam Sterilizer

The Steris AMSCO SG-136 Scientific Gravity Steam Sterilizer is a robust and efficient sterilization solution designed for reliable processing of heat- and moisture-stable materials. Featuring a spacious 26" x 37.5" x 36" (575 liters) chamber, it provides ample capacity to… -

Steris AMSCO SV-136 Scientific Medium Steam Sterilizer

The Steris AMSCO SV-136 Scientific Medium Steam Sterilizer is a high-capacity, pre-vacuum sterilizer designed for fast, reliable sterilization of heat- and moisture-stable materials. Featuring a spacious 26" x 37.5" x 36" (575 liters) chamber, it provides ample room to sterilize… -

Steris AMSCO SV-116 Scientific Steam Sterilizer

The Steris AMSCO SV-116 Scientific Steam Sterilizer is a high-performance, pre-vacuum sterilizer designed for reliable sterilization of nonporous, heat- and moisture-stable laboratory items. With a spacious 16" x 16" x 26" (109 liters) chamber, it accommodates a variety of laboratory… -

Steris AMSCO 630LS Medium Steam Sterilizer

The Steris AMSCO 630LS Medium Sterilizer is a versatile and energy-efficient steam sterilizer designed for scientific and healthcare applications. It offers a spacious chamber, ideal for larger loads, and supports a range of sterilization cycles including pre-vacuum, gravity, liquid, leak… -

Steris AMSCO 110LS 16” (110L) Lab Sterilizer

The Steris AMSCO 110LS Lab Sterilizer is a fully refurbished 16-inch steam sterilizer designed for reliable sterilization in laboratory and healthcare environments. It features an interior chamber measuring 16" x 16" x 26" (110 liters), equipped with a rack and… -

Steris AMSCO SG-116 Scientific Steam Sterilizer

The Steris AMSCO SG-116 Scientific Steam Sterilizer is a gravity-based sterilizer designed for the rapid sterilization of nonporous, heat- and moisture-stable goods, liquids, and media in life sciences and research settings. It features a 16" x 16" x 26" (109… -

Steris AMSCO 250LS 20” (250L) Lab Sterilizer

The Steris 250LS 20'' Lab Sterilizer is a state-of-the-art steam sterilizer that has been meticulously refurbished to ensure optimal performance. Designed with a spacious interior chamber measuring 20x20x38 inches, it accommodates a wide range of sterilization needs. This sterilizer features… -

Tuttnauer Model 69B-SCP Pre-Vac Steam Sterilizer

The Tuttnauer Model 69B-SCP Pre-Vac Steam Sterilizer boasts an impressive array of features designed to meet the rigorous sterilization needs of modern laboratories and medical facilities. With its spacious internal chamber dimensions of 24"W x 36"H x 48"D, this free-standing… -

Tuttnauer Plazmax P50 Hydrogen Peroxide Sterilizer

The PlazMax sterilizer inactivates micro-organisms with Hydrogen Peroxide (H2O2) vapor and plasma. It sterilizes medical devices by diffusing H2O2 into the chamber and then converting the H2O2 molecules into a plasma state. The sterilization occurs inside the chamber by means… -

Steris AMSCO LAB250 Steam Sterilizer

The Steris AMSCO LAB250 Steam Sterilizer is a compact, life-sciences oriented sterilizer designed for safe, reliable processing in research settings. It features a vertical sliding door with a non-lubricated steam-activated seal, a rugged vessel and reduced piping for dependability, and… -

Tuttnauer Plasmax 160 Hydrogen Peroxide Sterilizer

The PlazMax sterilizer inactivates micro-organisms with Hydrogen Peroxide (H2O2) vapor and plasma. It sterilizes medical devices by diffusing H2O2 into the chamber and then converting the H2O2 molecules into a plasma state. The sterilization occurs inside the chamber by means…

About Auxo Medical

Auxo Medical is a trusted provider of new and refurbished medical and laboratory equipment, serving facilities across the United States. With extensive experience in sterilization equipment sales, service, and support, we’re committed to helping life sciences facilities maintain the highest standards of quality and safety while optimizing their equipment investments.