Small Steam Sterilizer Refurbishment and Quality Assurance Process at Auxo Medical

Refurbished steam sterilizers from Auxo Medical offer a cost-effective and reliable solution for sterile processing needs, without compromising on quality or performance. With over 25 years of experience in process development and improvement, Auxo Medical takes a unique approach to refurbishment – a complete rebuild, ensuring “like new” warranties and performance.

The Auxo Medical Refurbishment Process: A True Rebuild

Unlike typical refurbishment processes, Auxo Medical’s approach involves a comprehensive rebuild of each steam sterilizer, guaranteeing optimal performance and longevity. This meticulous process includes:

1. Complete Disassembly at the Component Level

Every unit is completely disassembled, allowing for thorough inspection, cleaning, and replacement of worn or damaged parts.

2. Vessel and Frame Refurbishment

- Pressure Vessel Chamber: The pressure vessel chamber (“core”) undergoes bead blasting and hydrostatic pressure testing to ensure structural integrity.

- Frame/Stand: The cast iron framing/stand is bead blasted, repainted with rust-resistant paint, or completely replaced, ensuring a solid foundation.

- Insulation: A new insulation blanket encases the chamber/core, optimizing thermal efficiency.

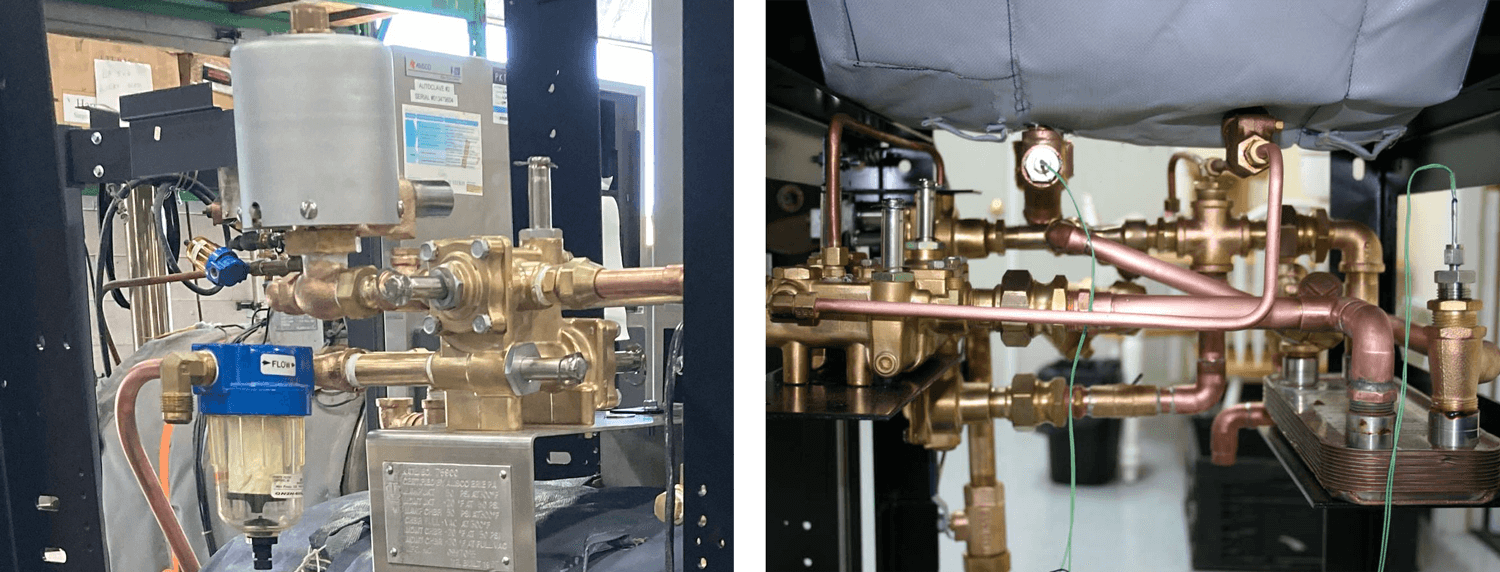

3. Plumbing Rebuild

Both upper and lower plumbing systems are meticulously rebuilt, with:

- Steam, Exhaust, and Water Manifolds: Rebuilt to ensure optimal flow and pressure.

- New Components (Upper Plumbing): Air filters, pressure gauges, pressure transducers, ball valves, and screens are replaced with new components.

- Rebuilt Components (Upper Plumbing): Pressure regulators and strainers are rebuilt to like-new condition.

- New Components (Lower Plumbing): Chamber sensor, ball valves, pressure switch, screens, o-rings, RTD, jacket, and chamber drain are replaced.

- Rebuilt Components (Lower Plumbing): Check valves, Venturi Water Ejector, heat exchanger, strainers, and steam traps are rebuilt.

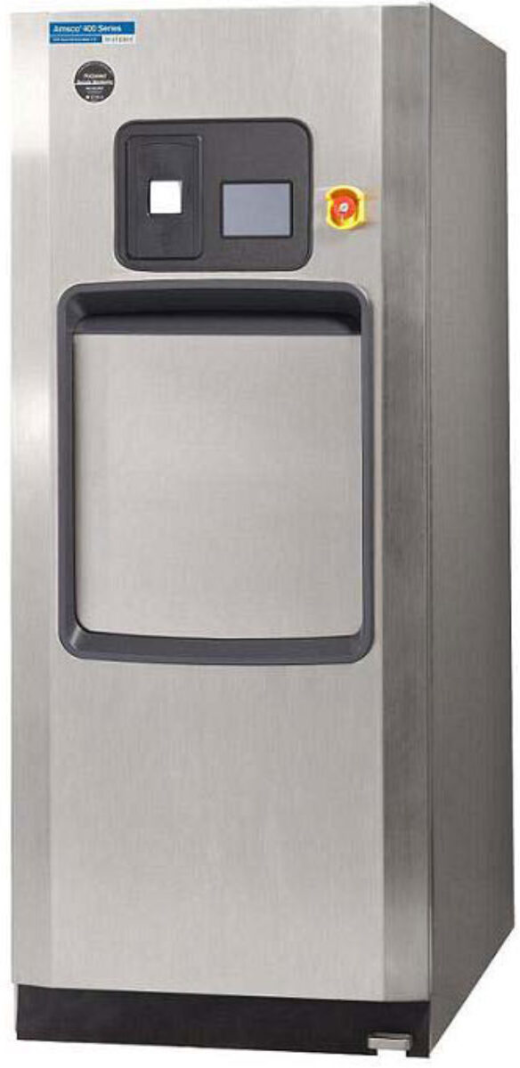

4. Door Refurbishment

Doors are disassembled, cleaned, and bead blasted as needed. Specific attention is given to different sterilizer models:

- 400 Series and Century Sterilizers (Vertical Power Door): Rebuilt with new door cable, sensors, stainless components, and a recertified motor.

- Eagle 3000 (Radial Handwheel Door): Rebuilt with refinished nickel-coated door bars, new guides, and a new door cover.

5. Controls Recertification

- Displays/Touchpads: Reconditioned or replaced to ensure clear and responsive operation.

- Printer Components: Replaced for reliable documentation.

- Control Board, Connector Board, Power Supply Board, Control Housing: Tested and recertified using an independent testing station.

- Wiring: All wiring is verified and replaced if necessary.

6. Framing/Stainless Panels

All other stainless and framing side panels are either new or regrained to achieve a “like new” condition, ensuring a professional appearance.

Quality Assurance: Ensuring Reliability and Performance

Auxo Medical’s commitment to quality extends beyond the refurbishment process. Every unit undergoes rigorous testing and calibration:

- Calibration: All units are meticulously calibrated to meet original manufacturer specifications.

- Leak Testing: Each unit must complete 20 cycles without exceeding a manufacturer-accepted leak rate of 1.0.

Benefits of Choosing Refurbished Steam Sterilizers from Auxo Medical

- Cost-Effective Solution: Obtain reliable sterile processing equipment at a fraction of the cost of new units.

- “Like New” Warranties: Enjoy peace of mind with warranties comparable to new equipment.

- Comprehensive Rebuild Process: Benefit from a meticulous refurbishment process that ensures optimal performance and longevity.

- Preventative Maintenance and Repair Support Options: Maximize uptime with available maintenance and repair services.

Contact Auxo Medical Today

Upgrade your sterile processing capabilities with confidence. Contact Auxo Medical to learn more about our refurbished steam sterilizers and explore preventative maintenance and repair support options.

Auxo Medical

Toll-Free: (888) 728-8448

-

Stainless Steel Side Panels for 400 Series 36in

Stainless Steel Side Panels for the 400 Series 36-inch Sterilizer are designed to provide durable, corrosion-resistant enclosure enhancements that protect the unit while enhancing its clinical aesthetics. Constructed from high-quality stainless steel, these panels offer superior durability in demanding hospital… -

36 inch cart and Carriage for 400 Series Sterilizer

The 36-inch cart and carriage for the Steris 400 Series 36-inch Sterilizer provide a robust, purpose-built transportation solution that ensures secure, stable handling of the recessed sterilizer. Designed to match the system’s dimensions, the cart features reinforced framing, smooth-rolling casters,… -

Steris 400 Series 36” House Steam Sterilizer Recessed

The Steris 400 Series 36" House Steam Sterilizer is a recessed, high-volume sterilization solution designed for efficiency and reliability. Its interior chamber measures 26 x 37.5 x 36 inches, with a fast, low-effort hinged-door option that locks or unlocks in… -

Steris Amsco 600 26.5 x 26.5 x 39″ Sterilizer

The Steris Amsco 600 is a sterilizer designed for efficient, high-volume processing, featuring a chamber with a 26.5 x 26.5" cross-section and a depth of 39" (450L volume). It offers 32 user-programmable cycle options, including pre-vacuum and gravity cycles, suitable… -

Steris 250LS 20” Lab Sterilizer

The Steris 250LS 20'' Lab Sterilizer is a state-of-the-art steam sterilizer that has been meticulously refurbished to ensure optimal performance. Designed with a spacious interior chamber measuring 20x20x38 inches, it accommodates a wide range of sterilization needs. This sterilizer features… -

Steris Amsco 400 Series 48” House Steam Sterilizer Recessed

The Steris AMSCO 400 Series Medium Steam Sterilizer, with its 48-inch recessed design and spacious 26 x 37.5 x 48-inch chamber, is engineered for efficient, high-volume sterilization. The chamber's dimensions optimize loading capacity, allowing for effective processing of larger loads.… -

Tuttnauer Model 69B-SCP Pre-Vac Steam Sterilizer

The Tuttnauer Model 69B-SCP Pre-Vac Steam Sterilizer boasts an impressive array of features designed to meet the rigorous sterilization needs of modern laboratories and medical facilities. With its spacious internal chamber dimensions of 24"W x 36"H x 48"D, this free-standing… -

48inch cart and Carriage for 400 Series Sterilizer

The 48-inch cart and carriage system designed for the Steris 400 series 48-inch sterilizer exemplifies top-tier engineering and convenience in modern healthcare environments. Tailored to perfectly fit and enhance the functionality of the Steris 400 series 48-inch sterilizer, this cart… -

Tuttnauer Plazmax P50 Hydrogen Peroxide Sterilizer

The PlazMax sterilizer inactivates micro-organisms with Hydrogen Peroxide (H2O2) vapor and plasma. It sterilizes medical devices by diffusing H2O2 into the chamber and then converting the H2O2 molecules into a plasma state. The sterilization occurs inside the chamber by means… -

Steris HC-900 Evolution Sterilizer

HC-900 26 x 37-1/2 x 42" Chamber AMSCO® Evolution® Steam Sterilizers are configured for prevacuum sterilization of heat- and moisture-stable materials used in healthcare facilities. These units can be equipped with prevacuum, Steam Flush Pressure Pulse (SFPP), gravity, liquid, and… -

Tuttnauer Plasmax 160 Hydrogen Peroxide Sterilizer

The PlazMax sterilizer inactivates micro-organisms with Hydrogen Peroxide (H2O2) vapor and plasma. It sterilizes medical devices by diffusing H2O2 into the chamber and then converting the H2O2 molecules into a plasma state. The sterilization occurs inside the chamber by means… -

Steris Amsco Stage 3 Series 20” 3023 Sterilizer

The refurbished Steris Amsco Stage 3 Series 20” 3023 Sterilizer offers a robust and reliable solution for demanding sterilization needs. Featuring a spacious 20" x 20" x 38" chamber and pre-vacuum (Class B) configuration, it ensures efficient and thorough sterilization… -

Steris Stage 3 Series 16″ 3013 Sterilizer

Refurbished Steris Amsco Model 3013 Steam Sterilizer includes: Stage 3 Controller with thermal printer, For Recess Mount, Chamber DIMS 16 x 16 x 26, Prevacuum (Class B), Thermal display with touchpad operation. [vc_btn title="Steris Amsco 16-20-3000 Cut Sheets" style="flat" shape="square"… -

Steris Amsco Century Small Sterilizer – Steris V120 Steam Sterilizer

The Steris Amsco Century Small Sterilizer (Steris V120 Steam Sterilizer), is an advanced solution tailored to meet the demands of today's operating rooms and various hospital environments. This sterilizer boasts a spacious chamber measuring 20" x 20" x 38", capable… -

Steris Amsco 400 Series 20″ Sterilizer

The refurbished Steris Amsco 400 Series 20" steam sterilizer offers a reliable and efficient solution for sterilization needs. Its 20"x20"x38" chamber accommodates a rack and two-shelf loading system, maximizing throughput. The single, foot-pedal actuated vertical power door simplifies loading and… -

Steris Amsco Eagle 3053

Refurbished Steris Eagle 3053 Steam Sterilizer Refurbished Steris Amsco Eagle 3000 Stage 3 series, 24″x 36″ x 60″, single door sterilizer. Recess mounted, or optional cabinet package. Model 3053. Pre-vac sterilizer, (3051 variant for gravity operation) with operating temperature of… -

Steris Amsco Eagle 3043

Request Quote Refurbished Steris Eagle 3043 Steam Sterilizer Refurbished Steris Amsco Eagle 3000 Stage 3 series, 24″x 36″ x 48″, single door sterilizer. Recess mounted, or optional cabinet package. Model 3043. Pre-vac sterilizer, (3041 variant for gravity operation) with operating temperature of… -

Steris Amsco Eagle 3033 Steam Sterilizer

The refurbished Steris Amsco Eagle 3033 Steam Sterilizer offers a large 24" x 36" x 36" chamber for high-volume sterilization needs. This recess-mountable unit (with optional cabinet package) features the advanced Stage 3 controller with a thermal printer for precise… -

Steris Amsco Century V160

Steris V160 Steam Sterilizers are designed for fast, efficient sterilization of heat and water-resistant materials with the same capabilities as a gravity sterilizer. The V160 pre-vacuum sterilizer is equipped with pre-vac, gravity, flash, express, leak test, and daily air removal… -

Steris V116 Steam Sterilizer

Refurbished Steris Amsco Model V116 Steam Sterilizer Steris V116 Steam Sterilizers are designed for fast, efficient sterilization of heat and water-resistant materials with the same capabilities as a gravity sterilizer. The V116 pre-vacuum sterilizer is equipped with pre-vac, gravity, flash,… -

Skytron Integrity 270 Sterilizer

The Integrity 270 stands as the workhorse of Skytron's Integrity line, setting new benchmarks for capacity and efficiency by processing up to sixteen 25-pound trays per cycle. This advanced sterilizer builds on Skytron's legacy of quality and innovation, offering solutions… -

Skytron Integrity 215 Sterilizer

Building on Skytron's legacy of quality and innovation, the Skytron Integrity 215 sterilizer stands out as a premier solution in a family of sterilizers designed to address the diverse needs of today's healthcare environments. Whether equipping a new facility, renovating… -

Skytron Integrity 175 Sterilizer

The Skytron Integrity 175 is engineered for compact efficiency, providing standard throughput within a space-saving footprint. Reflecting Skytron’s legacy of quality and innovation, the Integrity 175 is a member of a versatile family of sterilizers tailored to meet the diverse… -

Steris Amsco V136

Refurbished Steris Century V136 Steam Sterilizer Steris V136 Steam Sterilizers are designed for fast, efficient sterilization of heat and water-resistant materials with the same capabilities as a gravity sterilizer. The V136 pre-vacuum sterilizer is equipped with pre-vac, gravity, flash, express,…

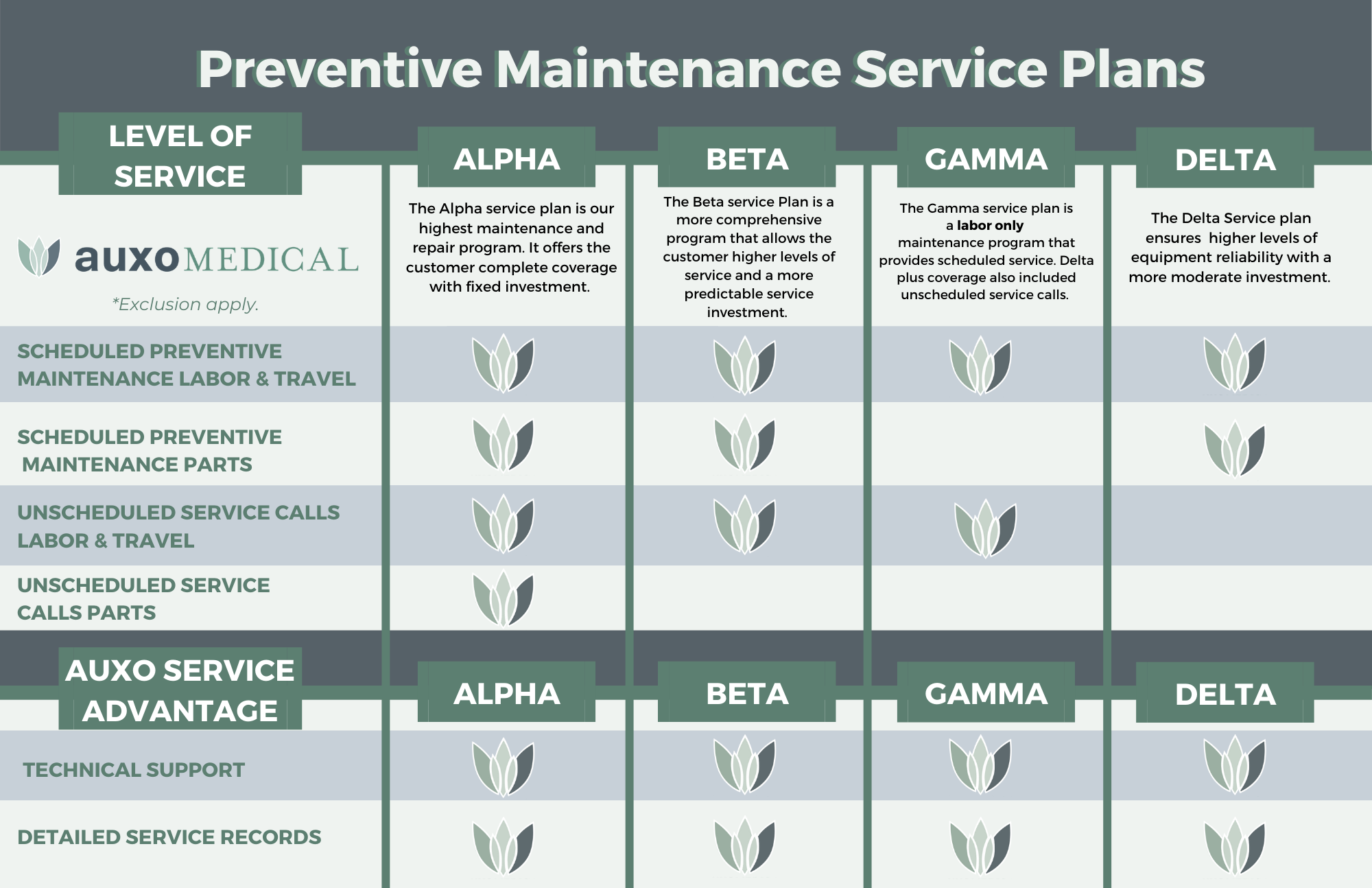

When it comes to ensuring the reliability and efficacy of your autoclaves and sterilizers, look no further than Auxo Medical for trusted preventative maintenance services. As a leading name in the industry, Auxo Medical is committed to providing comprehensive maintenance solutions that keep your essential equipment in top working condition and up to regulation standards. Regular servicing by our skilled technicians helps prevent unexpected breakdowns, extends the life of your machinery, and ensures compliance with stringent health and safety standards. Auxo Medical’s preventative maintenance plans are meticulously designed to address all aspects of sterilizer performance, from routine inspections to timely repairs, ensuring your operations run smoothly and efficiently. With Auxo Medical, you can have peace of mind knowing that your sterilization processes are in expert hands.

When it comes to ensuring the reliability and efficacy of your autoclaves and sterilizers, look no further than Auxo Medical for trusted preventative maintenance services. As a leading name in the industry, Auxo Medical is committed to providing comprehensive maintenance solutions that keep your essential equipment in top working condition and up to regulation standards. Regular servicing by our skilled technicians helps prevent unexpected breakdowns, extends the life of your machinery, and ensures compliance with stringent health and safety standards. Auxo Medical’s preventative maintenance plans are meticulously designed to address all aspects of sterilizer performance, from routine inspections to timely repairs, ensuring your operations run smoothly and efficiently. With Auxo Medical, you can have peace of mind knowing that your sterilization processes are in expert hands.